Dry Tank Technology Comparison with Conventional Systems

.

This page provides a detailed technical comparison between the performance of a conventional compressor system and one equipped with the Dry Tank Technology (DTT). This Dry Tank Technology comparison looks at three stages of compressor operation:

-

Conditions within the compressors before startup.

-

During the initial pressurization of the systems.

-

With the compressors are under load.

Contents

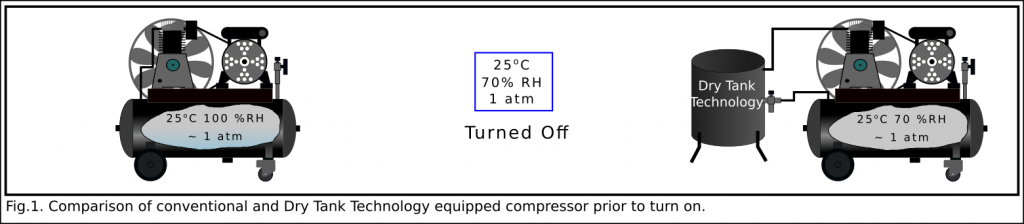

Compressors before starting

Both compressor systems are off. Have been sitting overnight in the workshop and are at the same temperature. DAS Technology compressor was working the previous day and has a dry receiver. Conventional compressor was working the previous day and has some water in the receiver.

Conventional Compressor: OFF Condition

Water in the receiver makes the uncompressed air above it saturated, therefore, the air has a relative humidity of ![]() . This air has a dew point temperature of

. This air has a dew point temperature of ![]() .

.

Dry Tank Technology Compressor: OFF Condition

The Dry Tank Technology receiver contains little or no water. The air in the receiver will have a dew point temperature a few degrees below ![]() .

.

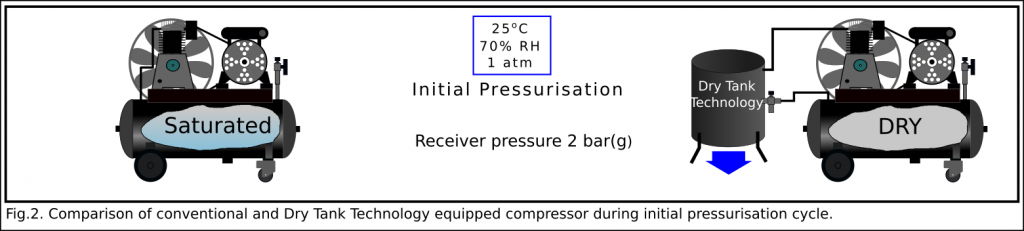

Compressors building up receiver pressure

The partial pressure of water vapour in ambient air at ![]() and

and ![]() is

is ![]() . Under these conditions, the ambient air has a saturated vapour pressure (SVP) of

. Under these conditions, the ambient air has a saturated vapour pressure (SVP) of ![]() and a dew point temperature of

and a dew point temperature of ![]() . Therefore, all the water in the ambient air is in the vapour phase. Since the receiver already contains some liquid water, the air above it is fully saturated, at

. Therefore, all the water in the ambient air is in the vapour phase. Since the receiver already contains some liquid water, the air above it is fully saturated, at ![]() . The compressor pressurizes the ambient air to

. The compressor pressurizes the ambient air to ![]() increasing the vapour pressure of the water in the system from

increasing the vapour pressure of the water in the system from ![]() to

to ![]() . The dew point temperature of the air in the receiver rises from

. The dew point temperature of the air in the receiver rises from ![]() (ambient saturated condition) to

(ambient saturated condition) to ![]() and the receiver starts to fill with water. Approximately

and the receiver starts to fill with water. Approximately ![]() of the water vapour content of the ambient air is compressed into a liquid. No liquid water is removed from the system at this point.

of the water vapour content of the ambient air is compressed into a liquid. No liquid water is removed from the system at this point.

Dry Tank Technology Compressor: Building up receiver pressure

The Dry Tank Technology module keeps the process pressure elevated above the receiver pressure. The water vapour pressure in the DTT module is about ![]() resulting in a dew point temperature of

resulting in a dew point temperature of ![]() . Maintaining the air at this pressure and cooling to ambient temperature results in the conversion of

. Maintaining the air at this pressure and cooling to ambient temperature results in the conversion of ![]() of the water content of the air into the liquid state. The receiver stores the air in a substantially dryer condition due to the removal of this water by the DTT module. The stored compressed air is water-free and as it is at a lower pressure, unsaturated.

of the water content of the air into the liquid state. The receiver stores the air in a substantially dryer condition due to the removal of this water by the DTT module. The stored compressed air is water-free and as it is at a lower pressure, unsaturated.

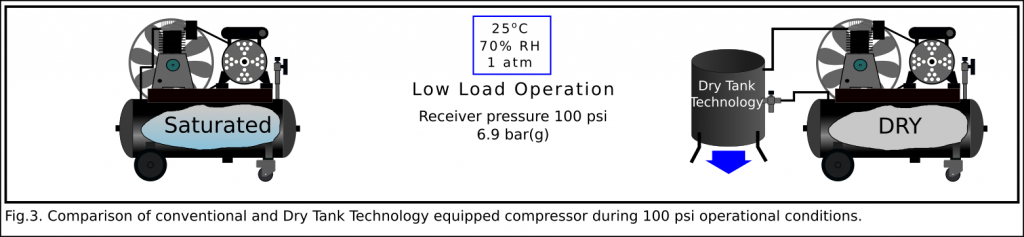

Compressors operating under low load conditions

The water vapour in the receiver has a partial pressure of ![]() and a temperature of

and a temperature of ![]() at

at ![]() . This temperature will rise with use, forcing more water into the vapour phase. The saturated air in the receiver has a dew point temperature of

. This temperature will rise with use, forcing more water into the vapour phase. The saturated air in the receiver has a dew point temperature of ![]() and an absolute humidity of

and an absolute humidity of ![]() .

. ![]() of the total water content of the air is in liquid form and lies in the receiver and various system component. As the temperature of the stored air increases the amount of water vapour that it can hold increases. At

of the total water content of the air is in liquid form and lies in the receiver and various system component. As the temperature of the stored air increases the amount of water vapour that it can hold increases. At ![]() ,

, ![]() of the water is now in the vapour phase. At

of the water is now in the vapour phase. At ![]() this increases to

this increases to ![]() . A pressure drop of 2 bar (process loadin) at this temperature will force nearly all the water into the vapour phase. This water vapour is therefor pumped throughout the whole system.

. A pressure drop of 2 bar (process loadin) at this temperature will force nearly all the water into the vapour phase. This water vapour is therefor pumped throughout the whole system.

Dry Tank Technology Compressor: Low Load conditions

The compressed air processed by the Dry Tank Technology module removes ![]() of the total water. This leaves the compressed air with an absolute humidity of

of the total water. This leaves the compressed air with an absolute humidity of ![]() . When moved to the receiver this air has a dew point temperature of

. When moved to the receiver this air has a dew point temperature of ![]() ,

, ![]() below ambient. The stored air is dry and unsaturated and hence able to support more water in the vapour phase. This allows a compressor system equipped with the DTT module to dry an otherwise wet compressor system. One of the other main advantages of the Dry Tank Technology is that the dryness of the air tracks with changes in the ambient temperature. A constant dew point temperature differential is hence maintained and dry gas consistently delivered.

below ambient. The stored air is dry and unsaturated and hence able to support more water in the vapour phase. This allows a compressor system equipped with the DTT module to dry an otherwise wet compressor system. One of the other main advantages of the Dry Tank Technology is that the dryness of the air tracks with changes in the ambient temperature. A constant dew point temperature differential is hence maintained and dry gas consistently delivered.

See Also

Benefits of Dry Tank Technology.

References

Dew Point in Compressed Air – Frequently Asked Questions, Vaisala Application Note, 2013. http://www.vaisala.com/Vaisala%20Documents/Application%20notes/Dew-point-compressed-air-Application-note-B210991EN-B-LOW-v1.pdf

Humidity Conversion Formulas, Calculations formulas for Humidity, Vaisala 2013. http://www.vaisala.com/Vaisala%20Documents/Application%20notes/Humidity_Conversion_Formulas_B210973EN-F.pdf